Added

Nov 21, 2024

Type

For Sale

Condition

new

Views

10

Country

India

States

Andhra Pradesh

City

Ratings:

(No Ratings Yet)

(No Ratings Yet)Description:

Company Profile

SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to USD one millon and its building covers 1000 square meters. Production equipment contains 25 sets of high precision punch, a set of vacuum heat treatment furnace (worth USD 100,000) as well as hundreds (sets) of various Tooling processing equipment and product testing equipment. There are more than 70 staffs ( 2 for research and development, 6 for die technology and 6 for quality control).

Key products of the company:

1. BeCu Gasket& Fingerstock, SMD BeCu Spring, BeCu Spring, shielded room Fingerstocks, Stainless steel Fingerstock, etc.

2. Precision Stamping Parts And Tooling, etc With All Kinds Of Metal Materials

3.Research&development And Production Of All Series Frabric-Over-Foam.

4. Design And Manufacture of Shielding Knitted Mesh And Shielding Honeycomb Panel.

5.Design and Manufacture Of Conductive Copper foil.

6.Research and Manufacture Of All Series Conductive Elaster

7.Design and Manufacture Of Shielding Glass.

8. Sales Of Other Electronic Materials.

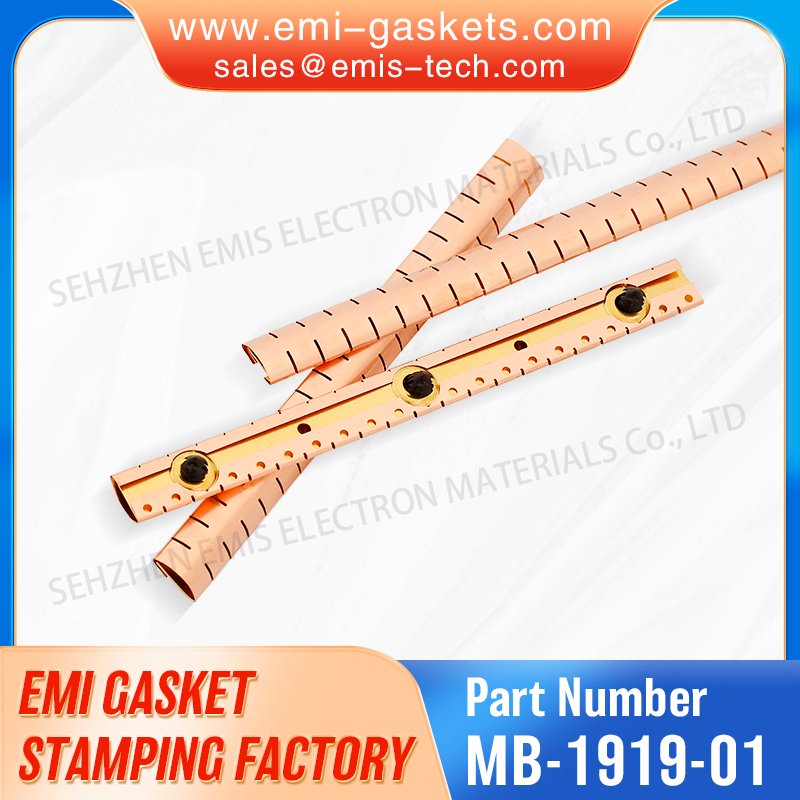

Product Introduction

Becu metal strip is a high-performance metal material made of beryllium copper (BeCu), which is widely used in scenarios requiring high strength, good conductivity and elasticity. Beryllium copper has unique properties such as fatigue resistance, corrosion resistance and high thermal conductivity, making it an important material for precision industry.

Features

High strength and high elasticity

Beryllium copper has a strength close to that of steel and excellent elasticity, making it suitable for elastic components such as springs and reeds.

Good electrical and thermal conductivity

Its electrical conductivity is about 15%-30% of copper, making it suitable for conductive parts and grounding systems.

Wear resistance and corrosion resistance

Beryllium copper has good corrosion resistance in acid, alkali and high humidity environments, and is suitable for harsh working conditions.

Antimagnetic and spark-free properties

Non-magnetic materials are not affected by magnetic fields; friction or impact in special environments will not produce sparks.

Machinability

Easy to cut, form and weld, and can be made into complex structural parts.

Main applications of beryllium copper metal strips

Electronic industry

Used for elastic contacts, connectors, shielding springs, signal transmission belts and other components that require high conductivity and high elasticity.

Power industry

Making grounding strips, contact pieces, etc. for high-voltage switches and electrical connection equipment.

Aerospace

Used as precision elastic components and anti-fatigue connectors to adapt to high stress environments.

Communication equipment

As shielding springs and grounding springs, used to shield signal interference and improve communication performance.

Mold manufacturing

The high strength and wear resistance of beryllium copper make it suitable for making cooling elements or heat-conducting elements in plastic molds.

Medical equipment

Used to manufacture precision instrument parts and contact electrodes to meet strict hygiene requirements.

Beryllium Copper Round Hollow Wire Mesh Gasket Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Two-Stage Liquid Ring Compressors | Kakati Pumps Category : Major Appliances Parts

(No Ratings Yet)

(No Ratings Yet)Spread the loveTwo-stage liquid ring compressors. Kakatipumps delivers outstanding performance & durability for various applications and industries across the globe.

We do PSP (PlayStation Portable) Motherboard Replacement Category : Other - Gaming

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe do PSP (PlayStation Portable) Motherboard Replacement @ from Ksh.4500 /= CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. For more, visit :

Alisan Smart Homes Category : Other Smart Home Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveAlisan Smart Homes is one of the leading Smart Homes Manufacturers in Haryana. Smart homes are revolutionizing the way we live by bringing automation to our daily lives. They are equipped with various devices and technologies that allow homeowners to control and manage their homes remotely. Welcome to Alisan Smart Homes, your premier

Repair Laptops Contact US Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe are based in Dadar, some 100 miles north of Mumbai, where the costs are considerably lower than the major conurbations such as Bangalore, Mumbai and Delhi. We are happy to pass these cost advantages on to our clients. This means that we provide technical support services from as little as £4 ($6)

Best Movie Production Companies Category : TV, Video & Home Audio Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveTop Movie Production Companies like Warner Bros., Universal Pictures, and Walt Disney Studios have consistently delivered cinematic masterpieces that captivate audiences globally. Known for high-quality storytelling, innovative visual effects, and iconic franchises, these companies set the industry standard. With their extensive resources and top-tier talent, they produce films across genres, from blockbusters to

High-Precision Spectrum Analyzer for Accurate Signal Analysis. Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveBoost your signal analysis accuracy with our advanced Spectrum Analyzer. Designed for precision in RF testing, this Spectrum Analyzer offers high-resolution measurement, real-time signal monitoring, and broad frequency coverage. Ideal for labs, telecommunications, and electronic testing, it ensures clear, reliable insights for optimizing signal performance. Visit us:- https://scientechworld.com/spectrum-analyzer/

Crypto Telegram Trading Bot Development : FireBee Techno Services Category : Desktops & All-In-One Computers

(No Ratings Yet)

(No Ratings Yet)Spread the love Fire Bee Techno Services advances in creating advanced Crypto Telegram Trading Bots, Customized to empower business professionals with smooth, automated trading via Telegram. These bots optimize trading by providing real-time market insights, swift order execution, and customizable settings for maximum efficiency and convenience. Key features include AI market predictions, support for multiple

Support HP Printers with Expert Assistance from HP Cart Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveGet reliable support for HP printers with HP Cart! Whether you’re facing connectivity issues, print quality problems, or setup challenges, our expert team is here to help. We specialize in troubleshooting and resolving all HP printer-related issues quickly and efficiently. Our support services ensure smooth operation, helping you get the most out of

What is the best PC to PC transfer software? Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking for the best PC to PC transfer software? Look no further! With the right tool, transferring files, applications, and settings between computers becomes seamless. Whether upgrading to a new PC or simply moving data, the ideal software makes the process fast and hassle-free. The best PC to PC transfer software allows you

Becu EMI Strip Becu Contacts Spring Availablefor PC& Servercase Grounding Solution Computer Gap Shielding Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Enjoy the Online Cricket Betting ID Experience For Online Gaming Category : Game Consoles

(No Ratings Yet)

(No Ratings Yet)Spread the loveVirat777, for instance, is a secure platform connecting you with the top betting platforms, bookmakers, and sportsbooks you can choose according to your choice and specific needs. Check all details and start your betting journey to play safely and wisely. It will be an ideal way to help you getting the best of

CCMS Lighting Solution in Delhi Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCCMS Lighting Solution in Delhi renders up-to-date, efficient management of street lighting facilities using the most advanced motion sensor technology for optimal performance. Further, keeping the infrastructure of smart cities in view, this CCMS lighting solution allows real-time monitoring and control while minimizing energy consumption and maintenance costs. The solution has motion sensors

Web Development Company in Shimla Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveSimran IT Services is one of the leading web development companies in Shimla.Our team of experienced web developers uses the latest technologies and best practices to build fast, secure, and scalable websites. We can create websites using a variety of programming languages, including PHP, Python, and JavaScript, and we can work with popular

Liquid Ring Vacuum Pump | Kakati Pumps Category : Other Major Home Appliances

(No Ratings Yet)

(No Ratings Yet)Spread the loveLiquid Ring Vacuum Pump, Kakatipumps are engaged in manufacturing and supplies a wide range of Pump that is used in various food processing industries

Red Alerts (Mistakes) To Avoid in Mean Stack Development Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveIn MEAN stack development, certain mistakes can derail projects if not addressed promptly. One major red alert is neglecting proper error handling; failing to manage errors can lead to poor user experiences and system crashes. Another common mistake is hardcoding configuration values instead of using environment variables; this practice reduces flexibility across different

Generator Dealers in Delhi | Best Generator Price in Delhi Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveGenerator dealers in Delhi. Best generator price in Delhi. Are you looking for generators in Delhi for residential or workspace? United Power Solution provide the best generator price in Delhi. Why Choose United Power Solution for the Best Generators for Reliable Energy Solutions in Delhi? Delhi is a city with a working environment

Responsive Website design in kolkata Category : Other - CTNH

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe at The SOFTECH provide Consulting Solutions and Business Analysis for our clients. We have been helping businesses grow, improve efficiencies, help manage expenses and increase effectiveness of business processes, sales results, revenues and net profits. We have worked with businesses from the start up stages, restructuring, changing of direction, organizations starting up

$0

$0

GE turbine control system maintenance in Stock. Buy, Repair, or Exchange from World of Controls

For SaleGE turbine control system maintenance in Stock. Buy, Repair, or Exchange from World of Controls Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveBuy, repair, or exchange GE turbine control system maintenance from World of Controls. We ship worldwide. Request a quote or contact our team for more details today. https://www.worldofcontrols.com/ge-turbine-control-system-troubleshooting

Becu EMI bar Becu fingerboard clip-on torque Becu bar Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to USD one

AWS Managed Services | Goognu Category : Other - CTNH

(No Ratings Yet)

(No Ratings Yet)Spread the loveMaximize your AWS environment with Goognu’s AWS Managed Services. Our team ensures seamless cloud management, enhanced security, and optimized performance for your business. Get in touch with Goognu today to take full advantage of AWS!

Anti Static Masterbatch Manufacturers – Capital Colours Category : Other - Home Surveillance Systems

(No Ratings Yet)

(No Ratings Yet)Spread the loveCapital Colours, your trusted source for anti static masterbatch manufacturers. Defend against electrostatic discharge and enhance your products Call.

Repair Laptops Contact US Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe are based in Dadar, some 100 miles north of Mumbai, where the costs are considerably lower than the major conurbations such as Bangalore, Mumbai and Delhi. We are happy to pass these cost advantages on to our clients. This means that we provide technical support services from as little as £4 ($6)

IoT Remote Monitoring Device | in India | CMSGP Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveIoT Remote Monitoring Device, CMSGP. Our State-of-the-art manufacturing floor adheres to various international standards & provides the scope. Contact

₹168.7906

₹168.7906

Factory Outlet with Large Price Advantage Metal Shielding Materails EMI Becu Shrapnel SMD Spring

For SaleFactory Outlet with Large Price Advantage Metal Shielding Materails EMI Becu Shrapnel SMD Spring Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to USD one

Get Your P2P cryptocurrency exchange software With Hivelance Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveP2P Crypto Exchange platforms allow users to trade cryptocurrencies directly with one another, without the involvement of a centralized exchange. This model offers unique advantages, making it an increasingly attractive option for individual investors and startups looking to enter the crypto market. Hivelance is the ideal partner for startups and businesses developing custom

SEO Company in Shimla Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveSimran IT Services- If you’re looking for a reliable and effective SEO company in Shimla, look no further than our team of experts. Contact us today to learn more about how we can help you grow your business online. For more details Call now +919418722224 or visit us at https://simranitservices.com/seo-company-shimla

Your Premier Offshore Development Partner | OpenTeQ Techonologies Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveOpenTeQ is a leading offshore development company, recognized as the best offshore development company for its innovative and cost-effective IT solutions. As a top offshore development company in Canada, we provide exceptional expertise and support to Canadian businesses, ensuring seamless project execution and outstanding results.

Crypto Exchange Development in India Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking to launch your cryptocurrency exchange? Partner with a trusted Crypto Exchange Development Company in India to turn your vision into reality. We specialize in creating secure, scalable, and feature-rich crypto exchange platforms tailored to your business needs. Whether it’s spot trading, futures, or P2P exchanges, our team delivers cutting-edge solutions with advanced

Street Lighting Solutions in India Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the love Street lighting solutions in India are always on the way to becoming more efficient with energy consumption and cost-cutting processes that make streets much safer. One promising solution would be with motion sensor technology, including auto-adjusting lights that sense who is near and lose light when there’s no one nearby, but illuminate

Welding Easily&Free Samples Twisted Series Contact EMI Strips Twist SMD Gasket Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

OLX Clone Script on Demand Classified Marketplace Software Category : Laptop & Desktop Accessories

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking for a OLX clone script to start your own classified marketplace? Our classified ads scripts can help you achieve the best results. With our script, users can easily create a classified marketplace website that is feature-rich and highly optimized. You can set up your classified site in just a few hours, getting

Reliable SLA 3D Printing Services for Precision and Quality Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveSLA 3D printing services offer high-precision, high-quality prototypes and models for various industries, including automotive, healthcare, and consumer goods. Using advanced stereolithography technology, these services produce intricate, detailed designs with smooth surface finishes. Ideal for functional prototypes, custom parts, and small-batch production, SLA 3D printing ensures accuracy and durability, making it a top

Husband and wife relationship problems Category : Other Smart Home Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the love Love Marriage Specialist, Love marriage problems solutions, Love problems solutions, get your lost love back Divorce problems solutions, Husband and wife relationship problems Husband want divorce and your want leave you? Do you want stop divorce from your husband, Taweez for love marriage, Taweez for lost love back, Taweez for divorce, Engagement

Top Best Video Production Agency, Company in Coimbatore Category : Other - Camera & Photo

(No Ratings Yet)

(No Ratings Yet)Spread the loveBVR Promos, the best video production company in Coimbatore, offers services like corporate ad films, animation, motion graphics, branding videos, testimonials, SaaS demos, and providing top-quality instructional videos to improve brand presence and engagement.

Top Securities Class Action Law Firms – Rosen Legal Category : Other - Camera & Photo

(No Ratings Yet)

(No Ratings Yet)Spread the loveRosen Law Firm is one of the leading securities class action law firms in the U.S. Our experienced attorney have recovered billions for investors. If you suffered losse

Web Development Services in Shimla Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveSimran IT Services is an award winning website development services in Shimla.We offer a range of web development services, including front-end development, back-end development, database design and integration, e-commerce development, and mobile-friendly website development. We work closely with our clients to understand their needs and objectives and to develop websites that meet their

https://www.imarque.com/blog/ Category : Laptops & Netbooks

(No Ratings Yet)

(No Ratings Yet)Spread the loveChennai, a thriving hub for Business Process Outsourcing (BPO) services, offers a wide range of outsourcing solutions to businesses across industries. Known for its skilled workforce, cost-effective solutions, and strong infrastructure, Chennai has emerged as one of the top destinations for BPO services in India. Leading BPO providers in Chennai offer services such

Top Casino Game Development Company Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking to build a casino app that stands out? As the leading casino game development company, Code Brew Labs specializes in delivering cutting-edge casino software solutions tailored to meet the dynamic demands of the gaming industry. From slot games to table classics, our expert developers create immersive experiences that captivate players. Partner with

High ROI Crypto Gaming Platform with Rollbit Clone Script – Book Your Free Demo! Category : Video Games

(No Ratings Yet)

(No Ratings Yet)Spread the loveThe Rollbit Clone Script is a pre-built software solution designed to replicate the success of Rollbit, offering features like cryptocurrency trading, NFT integration, and sports betting. This customizable solution empowers businesses to quickly launch their own platform. DappsFirm provides whitelabel Rollbit clone software at minimal cost and ensures a quick launch to accelerate

₹211.2379

₹211.2379

Custom EMI Shielding Gaskets and Spring Beryllium Copper Gaskets for MRI Doors and Windows

For SaleCustom EMI Shielding Gaskets and Spring Beryllium Copper Gaskets for MRI Doors and Windows Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Hot Selling EMI Contact Strips SMD Spring Large Enclosure Gasket Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to USD one

High ROI Crypto Gaming Platform with Rollbit Clone Script – Book Your Free Demo! Category : Video Games

(No Ratings Yet)

(No Ratings Yet)Spread the loveThe Rollbit Clone Script is a pre-built software solution designed to replicate the success of Rollbit, offering features like cryptocurrency trading, NFT integration, and sports betting. This customizable solution empowers businesses to quickly launch their own platform. DappsFirm provides whitelabel Rollbit clone software at minimal cost and ensures a quick launch to accelerate

Masterbatch Manufacturers In India | BSMasterbatch Category : Other - Home Surveillance Systems

(No Ratings Yet)

(No Ratings Yet)Spread the loveMasterbatch Manufacturers In India, BSMasterbatch. We play a pivotal role in the country’s plastic industry by providing high-quality products. Visit.

Sensor & Sensor Lighting Solutions in India Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the love Today’s sensor and sensor lighting solutions in India change the way spaces are lit with a trend seen through advanced energy-efficient technology. Among the sensor lighting solutions, motion sensor lights have been available for intelligent lighting control through movement detection, with luminosity activated only when necessary, saving unrequired amounts of power. In

India Customs Data | India Import Export Data Category : Surveillance & Smart Home Devices

(No Ratings Yet)

(No Ratings Yet)Spread the loveExim Trade Data Company provides precise India Import Export Data, enabling businesses to analyze market trends, track competitors, and discover new opportunities. Utilize our trusted data for better decision-making and business growth. For more information: Call: +91-9625812393 | Mail: Info@eximtradedata.com | Visit: https://eximtradedata.com/india-import-export-data

Becu EMI bar Becu fingerboard clip-on torque Becu bar Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to USD one

Web Development Company in Himachal Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveBoost your online presence with the best Web Development Company in Himachal. Simran IT Services offers professional, innovative solutions. Call +919418722224 or visit https://simranitservices.com/web-development-company-himachal/

We Install PS2 (PlayStation 2) USB games @ from Ksh.100 Category : Game Consoles

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe Install PS2 (PlayStation 2) USB games @ from Ksh.100 /= CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. For more, visit :

Revolutionize Your Games with Knick Global's Blockchain Expertise! Category : Other - Gaming

(No Ratings Yet)

(No Ratings Yet)Spread the loveTransform your gaming ideas into reality with Knick Global’s Blockchain Game Development Services! We create innovative games with NFT integration, secure smart contracts, and play-to-earn models, offering players true ownership of in-game assets. Drive engagement, boost revenue, and lead the gaming revolution. Contact Knick Global to get started today!

Liquid Ring Compressor – Kakati Pumps Category : Other - Home Surveillance Systems

(No Ratings Yet)

(No Ratings Yet)Spread the loveKakati Pumps Liquid Ring Compressor, designed for optimal efficiency in industrials applications. Our compressors are durable, reliable, and perfects.

Medical EMI Springs Standard EMI Springs Sufficient stock, accept small orders Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Remote Terminal Unit | Manufacturers India | CMSGP Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveRemote Terminal Unit, CMSGP. This device has a highly modular architecture with the flexibility to interchange its I/O modules. Visit now for details.

Production Houses in Delhi NCR Category : Other TV, Video & Home Audio Equipment

(No Ratings Yet)

(No Ratings Yet)Spread the loveProduction houses in Delhi NCR are dynamic centers offering comprehensive services for film, television, and digital media production. These companies specialize in creative content creation, including scripting, filming, editing, and post-production. With access to cutting-edge technology and skilled professionals, Delhi NCR production houses cater to diverse industries, delivering high-quality visual content for advertisements,

₹253.1646

₹253.1646

EMI Becu Spring Clip-on Perpendicular Grounding Strip EMI Communication Shielding Strips

For SaleEMI Becu Spring Clip-on Perpendicular Grounding Strip EMI Communication Shielding Strips Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

What to Do If You Need to Remove a Google Review Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveIf you find yourself needing to remove a Google review, it’s important to know the steps and policies involved. Start by reviewing the content to see if it violates Google’s guidelines—such as being fake, inappropriate, or defamatory. If the review breaches these rules, you can flag it for removal directly through your Google

Best Motion Sensor Light Bulbs for Home Security Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveEnhance your home security with motion sensor lights that combine convenience, energy efficiency, and advanced technology. The Motion Sensor LED Bulb by ESYSENSE is a standout choice, featuring cutting-edge smart sensor lighting that detects movement instantly and lights up your space. Ideal for both indoor and outdoor use, these bulbs are designed to

Join SpinMatch for Live IPL 2025 Betting Fun Category : Gaming

(No Ratings Yet)

(No Ratings Yet)Spread the loveSpinMatch takes your IPL 2025 experience to the next level with In Play Betting. Stay active during live matches, placing your bets based on real-time events. If you’re looking for an extra thrill, this feature is your ultimate companion!

Fast Delivery&Free Samples EMI Copper Finger Gasket EMI Shielding Strips Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to USD one

High ROI Crypto Gaming Platform with Rollbit Clone Script – Book Your Free Demo! Category : Video Games

(No Ratings Yet)

(No Ratings Yet)Spread the loveThe Rollbit Clone Script is a pre-built software solution designed to replicate the success of Rollbit, offering features like cryptocurrency trading, NFT integration, and sports betting. This customizable solution empowers businesses to quickly launch their own platform. DappsFirm provides whitelabel Rollbit clone software at minimal cost and ensures a quick launch to accelerate

VIP BOOK is India's top platform for Online cricket ID and offers Multiple games. Category : Other - Gaming

(No Ratings Yet)

(No Ratings Yet)Spread the loveVIP BOOK is India’s best Online Cricket ID and Cricket Betting ID provider. VIP BOOK offers 24*7 support, utmost transparency & Security in Online Cricket IDs. https://vipbookofficial.com/

Production Houses in Delhi NCR Category : Other TV, Video & Home Audio Equipment

(No Ratings Yet)

(No Ratings Yet)Spread the loveProduction houses in Delhi NCR are dynamic centers offering comprehensive services for film, television, and digital media production. These companies specialize in creative content creation, including scripting, filming, editing, and post-production. With access to cutting-edge technology and skilled professionals, Delhi NCR production houses cater to diverse industries, delivering high-quality visual content for advertisements,

Top-Notch iPhone Repairing Services – King Wireless & Phone Repair Category : Cell Phone Accessories

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking for reliable iphone repairing services? Look no further! At King Wireless & Phone Repair, we are the #1 choice for fast, affordable, and professional iPhone repairs. 📱 Our iPhone Repairing Services Include: Cracked Screen Repairs Battery Replacements Charging Port Fixes Water Damage Recovery Camera & Speaker Repairs Software Issues & Updates ⏱

Easy Live Sports Betting Script for Real-Time Casino Excitement Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking to enhance your casino platform with engaging mini games? Dappsfirm offers readymade mini game scripts at minimal cost, including popular options like aviator, Dice, Arcade, Crash, Roulette, and Wheel games. Our custom mini games for casinos are designed to elevate user experience and boost engagement. Whether you’re interested in in-house mini games

Motion Sensor Manufacturers in India Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSmart lighting solutions are among the many high-end motion sensor manufacturers in India that create cutting-edge sensor solutions for various applications. The sensors are intended to maximize energy efficiency and are made to detect movement. As a result, their potential increases their suitability for commercial, industrial, and residential settings. Indian manufacturers are meeting

The Impact and Evolution of Netflix: Transforming the Entertainment Landscape Category : Cell Phones & Smartphones

(No Ratings Yet)

(No Ratings Yet)Spread the loveNetflix, a leading streaming service known for its wide variety of movies, TV shows, and original content, has become a central figure in the global entertainment industry. Founded in 1997 by Reed Hastings and Marc Randolph, Netflix started as a DVD rental service by mail but evolved into a streaming juggernaut that has

BEE Registration Complete Process Category : Other - CTNH

(No Ratings Yet)

(No Ratings Yet)Spread the loveAgile Regulatory offers expert support for obtaining BEE registration in India, ensuring products meet the Bureau of Energy Efficiency standards. We guide you through every step, from preparing documents to managing the application process, helping businesses meet regulatory requirements for energy efficiency labeling. Our team simplifies the process so you can focus on

All Metal, Foam or Elastomer Knitted Wire Mesh Gasket Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Business Interior Design in Navi Mumbai Category : Home Audio Systems

(No Ratings Yet)

(No Ratings Yet)Spread the loveWelcome to Holla Homes, your premier interior design company in Navi Mumbai dedicated to transforming spaces into luxurious and functional environments. With years of expertise in the field, we specialize in creating customized interior designs that reflect your unique style and preferences. Our team of skilled designers takes pride in delivering innovative solutions

Get effective and attractive dubbing services Category : Other - Portable Audio

(No Ratings Yet)

(No Ratings Yet)Spread the loveIf you want to achieve exceptional dubbing quality, it’s vital to collaborate with a professional service that ensures your content feels natural and authentic in the target language. Whether your project involves films, TV shows, video games, or corporate presentations, the right dubbing partner can elevate your message. Get in touch with us

Best Motion Sensor Light Bulbs for Home Security Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveEnhance your home security with motion sensor lights that combine convenience, energy efficiency, and advanced technology. The Motion Sensor LED Bulb by ESYSENSE is a standout choice, featuring cutting-edge smart sensor lighting that detects movement instantly and lights up your space. Ideal for both indoor and outdoor use, these bulbs are designed to

Best Online Cricket ID for Seamless Gameplay & Ultimate Experience Category : Gaming

(No Ratings Yet)

(No Ratings Yet)Spread the loveUnlock the best online cricket experience with our premium Cricket ID, designed for smooth gameplay, exclusive features, and top-tier performance. Whether you’re a beginner or a seasoned player, our Cricket ID ensures access to exciting tournaments, customized features, and secure connections, all while giving you an edge in the game. Join a community

Affordable Custom Mini Game Scripts for Casino Engagement Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking to enhance your casino with engaging mini games? Dappsfirm offers ready-made mini game scripts at minimal cost, including aviator game, Dice Game, Arcade, Crash, Roulette, and more! Whether you need add-on mini games for your casino or custom in-house games, we’ve got you covered. Our versatile mini casino games like Wheel of

Second Hand Laptops in Mumbai Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveDo you want a good dealer for a second laptop in Mumbai, and do you want a second laptop in good condition? Do you need a second hand laptop at the cheapest rate? Then not to worry about this Raza Computers is there to fulfil all your needs for a second hand laptop

Repair Laptops Contact US Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe are based in Dadar, some 100 miles north of Mumbai, where the costs are considerably lower than the major conurbations such as Bangalore, Mumbai and Delhi. We are happy to pass these cost advantages on to our clients. This means that we provide technical support services from as little as £4 ($6)

Get Expert Web Development Services Category : Other - CTNH

(No Ratings Yet)

(No Ratings Yet)Spread the loveUnlock the potential of your business with professional web development services from Nexcess Technologies. Our team of experts specializes in creating custom websites that are responsive, user-friendly, and designed to meet your specific business needs. Whether you need a simple website or a complex web application, we provide tailored solutions that deliver results.

Developer Affirmations for Peak Laravel Performance Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the love Achieving peak performance in Laravel development involves adopting a mindset focused on continuous improvement and efficiency. Developers should affirm their commitment to writing clean, maintainable code while embracing best practices such as adhering to the DRY (Don’t Repeat Yourself) principle. Regularly participating in code reviews fosters collaboration and knowledge sharing among peers.

Leverage the Power of our Coinbase Clone Script to Build Your Crypto Exchange Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveWant to make a quick entry into the surging crypto market? Plurance is the leading cryptocurrency exchange development company that can help you launch your crypto exchange quickly and speed your business growth, with our Coinbase clone script. We offer cutting-edge white-label Coinbase clone software that empowers you to customize and launch your

Data Entry Services Company Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveFusion Digitech is widely regarded as one of the best data entry services companies in the USA, offering top-notch solutions to businesses across various industries. With a strong focus on accuracy, efficiency, and security, Fusion Digitech provides a wide range of data entry services, including data processing, form filling, data mining, and document

Free Customized Low Compression Force BeCu Fingerstock Gaskets Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Data entry services in the USA Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveData entry services in the USA are a vital aspect of many industries, providing businesses with essential support in managing and organizing large volumes of information. These services typically involve the accurate and efficient input of data into digital systems, databases, or software applications. They are essential in sectors such as healthcare, finance,

Repair Laptops Contact US Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe are based in Dadar, some 100 miles north of Mumbai, where the costs are considerably lower than the major conurbations such as Bangalore, Mumbai and Delhi. We are happy to pass these cost advantages on to our clients. This means that we provide technical support services from as little as £4 ($6)

About Us – GameApp Online | Big Mumbai & Prediction Games Category : Gaming

(No Ratings Yet)

(No Ratings Yet)Spread the loveExplore GameApp Online, your destination for Big Mumbai and thrilling prediction games. Dive into our immersive platform where players can enjoy various games inspired by iconic locations. Test your prediction skills, connect with fellow gamers, and compete to win real rewards. Whether you’re here for casual fun or serious gaming, GameApp Online brings

Buy Freelancer PHP Script for Your Online Marketplace Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveAre you looking to create a functional online freelance marketplace like the popular online marketplace Freelancer? Save your money and time with our superior quality, affordable, and fully customizable freelancer PHP script. Our pre-built freelancer scripts are equipped with a wide range of features including a powerful admin panel, project management, dispute management,

Becu Fingerstock EMI Becu Strips Slot Mounted Series Gasket Top Sale Item Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Web Development Company in Solan Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe At our web development company Simran IT Services in Solan. We specialise in creating custom websites and web applications that are tailored to meet the unique needs of our clients. Whether you’re looking to build a simple website to showcase your business or a complex web application to automate your operations, have

Elevate Your Business with the Best Billing Software for PC Category : Laptop & Desktop Accessories

(No Ratings Yet)

(No Ratings Yet)Spread the loveFinding the right billing software for PC is essential for businesses looking to manage their financial transactions effectively. This POS software typically provides a wide range of features, including invoicing, expense tracking, and financial reporting, all designed to streamline accounting processes. With an user-friendly interface and customizable options, users can easily handle billing

SEO Company in Mandi Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveSimran IT Services is Our SEO company in Mandi specialises in providing top-notch search engine optimization services to businesses of all sizes. We have a team of experienced SEO experts who are dedicated to improving your website’s visibility, driving more traffic. For more details Call now +919418722224 or visit us at https://simranitservices.com/seo-company-mandi

Web Development Services in Solan Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveOur company provides high-quality web development services in Solan, Himachal Pradesh. We specialise in creating custom websites for businesses of all sizes, from small startups to large enterprises.For more details Call now +919418722224 or visit us at https://simranitservices.com/web-development-company-solan

Oxo Biodegradable Plastic Manufacturers – Capital Colour Category : Other - Home Surveillance Systems

(No Ratings Yet)

(No Ratings Yet)Spread the loveOxo Biodegradable plastic manufacturers. Capitalcolours provide masterbatches helps the plastic product to destroy so that plastic waste can go back to earth.

How Meon Offers the Best Electronic Signature Online for You? Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveMeon offers a seamless and secure electronic signature solution that streamlines your document workflows. With Meon’s user-friendly interface, you can easily upload your documents and send them for signature to multiple parties. Our advanced security measures ensure the confidentiality and integrity of your sensitive information. So that there is no risk of online

We do PlayStation 2 {PS2} USB chipping @ from Ksh.2000 Category : Desktops & All-In-One Computers

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe do PlayStation 2 {PS2} USB chipping @ from Ksh.2000 /= CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. For more, visit :

Electromagnetic shielding assembly shrapnel Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

EMI RFI shielding Knitted Wire Mesh Gasket Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Color Masterbatches | BS Masterbatch Category : Other - Home Surveillance Systems

(No Ratings Yet)

(No Ratings Yet)Spread the loveColor Masterbatches, BSMasterbatch. Our key strength lies in engaging the customers and delivering exactly what has been promised. Contact for details

TECHExpert India | TECHExpert Engineering Pvt Ltd | Pune Category : Washers, Dryers, Parts & Accessories

(No Ratings Yet)

(No Ratings Yet)Spread the loveWorld-class Paint Finishing System by TECHExpert India for efficient Surface Finishing System, Paint Finishing System (Paint Booth System), Powder Coating System, Pre-Treatment System, Shot Blasting System, Material Handling System, Industrial Ovens/Curing Oven System, and Environmental Technology and more

Launch a SkyExchange-Like Betting Platform Today with Our Skyexchange Clone Script Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveSkyExchange clone script is a ready-made solution to build a betting platform similar to SkyExchange. It offers comprehensive features for sports betting, live betting, and online wagering, replicating the functionalities of the original platform. Dappsfirm provides whitelabel SkyExchange clone software at minimal cost, allowing businesses to quickly launch their own custom betting site.

We do replace PlayStation 2 {PS2} motherboard @ from Ksh.4500 Category : Game Consoles

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe do replace PlayStation 2 {PS2} motherboard @ from Ksh.4500 /= CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. For more, visit :

Smart Lighting Solution in Delhi Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSmart lighting solutions in Delhi are changing the way people manage energy efficiency and convenience in homes and businesses. Advanced motion sensors ensure that lights automatically turn on or off according to movement, optimizing energy usage and enhancing security. Sensor-based solutions are perfect for urban environments, proposing cost-effective and more environmentally friendly lighting

We do Lens repair for PlayStation 2 {PS2} @ from Ksh.1500 Category : Game Consoles

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe do Lens repair for PlayStation 2 {PS2} @ from Ksh.1500 /= CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. For more, visit

7 Parameters for a Smooth MEAN Stack Development Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveSuccessful MEAN stack development hinges on several critical parameters that ensure smooth project execution. First, selecting the right tools for each layer—MongoDB, Express.js, AngularJS, and Node.js—is essential for cohesive integration. Second, establishing clear coding standards promotes consistency across the codebase. Third, implementing version control systems like Git facilitates collaboration among developers. Fourth, prioritizing

Choose Dx Ham Radio Supply for All Your Radio Needs! Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveAre you an amateur radio enthusiast looking for top-quality ham radio supplies? Explore Dx Ham Radio Supply! We offer a comprehensive selection of products to help you connect with fellow hams around the globe. At Dx Ham Radio Supply, we pride ourselves on providing exceptional Ham radio supplies. Our knowledgeable team is passionate

Elevate Your Business with the Best Billing Software for PC Category : Laptop & Desktop Accessories

(No Ratings Yet)

(No Ratings Yet)Spread the loveFinding the right billing software for PC is essential for businesses looking to manage their financial transactions effectively. This POS software typically provides a wide range of features, including invoicing, expense tracking, and financial reporting, all designed to streamline accounting processes. With an user-friendly interface and customizable options, users can easily handle billing

Ace Combat 7 Skies Unknown Category : Game Consoles

(No Ratings Yet)

(No Ratings Yet)Spread the loveAce Combat 7 Skies Unknown Laptop/Desktop Computer Game. PRICE : ksh 800.00 CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. Minimum Graphics Card

We install PlayStation 3 {PS3} games @ from Ksh.500 /= Category : Game Consoles

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe install PlayStation 3 {PS3} games @ from Ksh.500 /= CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. For more, visit : www.XGAMERtechnologies.com/services

Overcoming Rigidity in MEAN Stack Development Projects Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveRigidity in MEAN stack development projects often stems from outdated practices or resistance to change within teams. To overcome this challenge, fostering a culture of adaptability is crucial; encouraging team members to embrace new technologies enhances innovation potential. Regularly revisiting project goals ensures alignment with evolving market demands while allowing for adjustments in

Develop Your Own Sports & Crypto Prediction Game with a Plug-and-Play Script Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveA Prediction Game Script enables the creation of platforms where users can predict outcomes of various events like sports, politics, or crypto markets. It can be customized as a bespoke Prediction Game Clone or a whitelabel Prediction Game Clone Script to suit specific needs. These scripts offer seamless integration, real-time updates, and reward

Low resistance SMD Becu gold plated spring Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

We repair / replace PlayStation 2 {PS2} power switch Category : Video Games

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe repair / replace PlayStation 2 {PS2} power switch @ from Ksh.1000 /= CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. For more,

Best Matchmaking Platforms for NRIs – Your Ideal Partner Awaits Category : Other Major Home Appliances

(No Ratings Yet)

(No Ratings Yet)Spread the loveExplore leading NRI matchmaking websites that combine tradition and technology. Find professional matchmaking services designed for the global Indian community seeking meaningful connections.

Best SEO Services in Shimla Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveIf you’re looking for an experienced and reliable SEO partner in Shimla, Simran IT Services is a leading SEO company in Shimla,Contact us today to learn more about our services and how we can help your business succeed online.For more details Call now +919418722224 or visit us at https://simranitservices.com/seo-company-shimla

Masterbatch Exporters | BSMasterbatch Category : Other - Home Surveillance Systems

(No Ratings Yet)

(No Ratings Yet)Spread the love Masterbatch Exporters, BSMasterbatch. We are a fast-moving company that offers diverse and unique options to our clients and customers. Contact us now

OLX Clone Script on Demand Classified Marketplace Software Category : Laptop & Desktop Accessories

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking for a OLX clone script to start your own classified marketplace? Our classified ads scripts can help you achieve the best results. With our script, users can easily create a classified marketplace website that is feature-rich and highly optimized. You can set up your classified site in just a few hours, getting

We repair PlayStation 3 {PS3} gamepads @ from Ksh.500 /= Category : Game Consoles

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe repair PlayStation 3 {PS3} gamepads e.g. analog button replacement @ from Ksh.500 /= CONTACT : 0786 178372 or 0726 178372 LOCATION : Shop 501 (5th floor), Veteran House (Graffins college) Moi avenue, Nairobi Kenya Google pin : https://maps.app.goo.gl/K887Wbk5Be14K3mV9 We open everyday 8am → 8pm. Sunday’s & public holidays 11am → 5pm. For

Talcum Powder Blending Machine Manufacturing in India-Mumbai Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveIf You Are Looking for Talcum Powder Blending Machine Manufacturing in Mumbai India, Fansbro erectors is the better choice. Talcum powder blending machines are essential for achieving uniformity and quality in the production of talcum powder, widely used in cosmetics, personal care products, and pharmaceuticals. Small enterprises and startups may be able to

Becu Spring Becu Fingerboard EMI Spring Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

SMD springs are not deformed when compressed Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Best PCB Fabrication Service in Ahmedabad | +91 9227020017 Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveWould you be able to find high-quality PCB fabrication services in Ahmedabad? We specialize in manufacturing precision-engineered printed circuit boards tailored to meet your needs. With advanced technology and skilled expertise, we deliver durable, reliable, and efficient PCBs for various industries. Get your PCB solutions from Ahmedabad’s trusted experts! Contact us today with

Monitoring IoT Devices | Manufacturers India | CMSGP Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveMonitoring IoT Devices, CMSGP. We are constantly evolving along with our technology to meet every challenge in the domain. Contact us for more details

Revolutionize Your Pharmaceutical Operations with Absolute ERP! Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveAbsolute ERP offers a powerful, industry-specific ERP solution tailored to meet the unique challenges of the pharmaceutical sector. With Absolute ERP, you gain advanced tools to streamline compliance, enhance inventory control, improve production quality, and ensure traceability across all operations. By providing real-time insights and automated workflows, Absolute ERP helps pharmaceutical businesses reduce

₹422.4043

₹422.4043

Becu Spring Becu Fingerstock EMI Spring Large Enclosure Gasket Mature Process Stable Quality

For SaleBecu Spring Becu Fingerstock EMI Spring Large Enclosure Gasket Mature Process Stable Quality Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

IS230TSPRH1C in Stock. Buy, Repair, or Exchange from World of Controls Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveBuy, repair, or exchange IS230TSPRH1C from World of Controls. We ship worldwide. Request a quote or contact our team for more details today. https://www.worldofcontrols.com/is230tsprh1c

Social Media Marketing Services In Navi Mumbai Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveBoost your brand’s online presence with Social Media Marketing Services in Navi Mumbai from Pridex Digital. We specialize in creating tailored strategies to engage your audience, drive traffic, and enhance conversions. From impactful content creation to targeted ad campaigns, our expert team ensures your business stands out across platforms. Empower your growth with

₹168.7906

₹168.7906

Factory Outlet with Large Price Advantage Metal Shielding Materails EMI Becu Shrapnel SMD Spring

For SaleFactory Outlet with Large Price Advantage Metal Shielding Materails EMI Becu Shrapnel SMD Spring Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to USD one

EMI Contact Strip Becu Spring EMI Shielding Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

India Customs Data | India Import Export Data Category : Home Sensors & Motion Detectors

(No Ratings Yet)

(No Ratings Yet)Spread the loveUnlock market potential with Exim Trade Data’s reliable India Import Export Data for global trade success. For more information: Call: +91-9625812393 | Mail: Info@eximtradedata.com | Visit: https://eximtradedata.com/india-import-export-data

Motion Sensor Lightings in India Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the love Motion sensor lighting in India is revolutionizing the approach of houses and offices towards energy efficiency and convenience. Advanced motion sensor technology in smart lighting solutions illuminates spaces only when movement is detected, thereby reducing waste and enhancing security. Motion sensor lighting is the perfect sensor solution for modern living, and it

₹845.2370

₹845.2370

EMI high shielding performance honeycomb high temperature vacuum brazed honeycomb vents

For SaleEMI high shielding performance honeycomb high temperature vacuum brazed honeycomb vents Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Independent Call Girls & Escort Services in Jaipur | cglook Category : Other - Camera & Photo

(No Ratings Yet)

(No Ratings Yet)Spread the loveCglook offers reliable and accessible services, available both online and offline, to meet a variety of customer needs. We pride ourselves on delivering quality support and solutions, ensuring our clients receive timely assistance and expertise, no matter where they are. Independent Call Girls in jaipur

Becu Contact Strips Becu Clip-on Strips SMD Spring Anti Interference Shielding Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Plastic Masterbatch Manufacturer In India – Capital Colours Category : Other - Home Surveillance Systems

(No Ratings Yet)

(No Ratings Yet)Spread the loveTransforming plastics with excellence: Plastic masterbatch manufacturer in India. We creates vibrant, durable, and sustainable solutions Call Us Now

Exploring Bigpond: A Reliable Choice for Your Internet Needs Category : Laptop & Desktop Accessories

(No Ratings Yet)

(No Ratings Yet)Spread the loveBigpond is Australia’s Internet service provider(ISP),which provides services, such as Email Services, ADSL, Cable internet and Dialup. Also BigPond is known as Telstra.It provides reliable internet networks in Australia.Earlier Telstra was a state-owned company, Now Telstra is a fully private company. In recent times, it is primarily focusing on various Tech products and

Best Room Heater for Winter in India Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveLooking for an efficient and safe heater for small rooms? The Orpat OEH-1220 should be your pick. It’s powerful yet energy-efficient, with dual heat settings (1000W/2000W) for customizable warmth. The built-in fan circulates heat evenly, making the entire room comfortable quickly. I also appreciate its safety features, like overheat protection, which ensures peace

Biggest Film Production Company in Delhi Category : Other TV, Video & Home Audio Equipment

(No Ratings Yet)

(No Ratings Yet)Spread the loveGenesis Media Pvt. Ltd. is the Biggest Film Production Company in Delhi, offering top-notch services for movies, advertisements, and corporate videos. With a proven track record of creative excellence and cutting-edge technology, we bring your vision to life. Our team specializes in storytelling that captivates audiences and delivers exceptional results for clients across

High-Quality PCB Fabrication Services | 9879420017 | Fine Trak Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveAt Fine Trak Systems, we specialize in delivering top-notch PCB Fabrication Services, tailored to the unique requirements of diverse industries. With a highly skilled team and cutting-edge manufacturing facilities, we ensure precision and quality in every project. We take pride in our expertise across all phases of PCB fabrication. our team supports you

Best SEO Services in Mandi Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveOur company Simran IT Services offers the Best SEO Services in Mandi with a team of experienced SEO professionals that uses the latest tools and techniques to optimize your website and make it more search engine friendly. We conduct a comprehensive analysis of your website, identify areas that need improvement, and devise a

A dab pen, also known as a wax pen or concentrate vaporizer Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveExplore the Best Dab Pens at Lookah Looking for the ultimate vaping experience? Check out our top-quality dab pens designed for smooth, flavorful hits every time. Whether you’re a beginner or a seasoned user, Lookah has the perfect vaporizer for you! Discover more: https://www.lookah.com/vaporizers/ #DabPen #VapingEssentials #LookahVaporizers A dab pen, also known as

Radar Motion Sensor Bulb Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveThe Radar Motion Sensor Bulb by ESYSENSE is a smart and energy-saving lighting option. This Motion Sensor LED Bulb 10W Cool White activates automatically when it detects movement and turns off after no motion is detected, helping conserve energy. Featuring advanced radar technology, it senses motion through walls, glass, and other obstacles, offering

Overcoming Remote Laravel Teams Disconnection Case Studies Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the love Remote Laravel teams often face disconnection challenges that can affect project outcomes. Case studies reveal effective strategies for overcoming these hurdles. For instance, implementing regular video calls fosters personal connections among team members, enhancing collaboration. Utilizing project management tools like Trello or Jira ensures everyone stays aligned on tasks and deadlines. Additionally,

₹253.1859

₹253.1859

Professional Supplier in China EMI Stainless Steel Spring Berryllium Copper Fingerstock and Gaskets

For SaleProfessional Supplier in China EMI Stainless Steel Spring Berryllium Copper Fingerstock and Gaskets Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveSHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to USD one

8 Quick Fixes to achieve a Flexible MEAN architecture Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveAchieving a flexible MEAN architecture involves implementing several quick fixes that enhance adaptability and scalability. First, modularizing components allows for easier updates without affecting the entire system’s functionality. Second, adopting microservices architecture enables independent deployment of services for greater flexibility in scaling applications based on demand. Third, integrating containerization technologies like Docker simplifies

Exploring the Future of Art: 3D Printing for Art in India Category : Laptop & Desktop Accessories

(No Ratings Yet)

(No Ratings Yet)Spread the love3D printing for art in India is the new revolution of the artistic scene because with the accuracy and efficacy, complicated designs are brought to life. The technology it provides for offering boundless sculptural installations with combined media allows both traditional and modern artists to try novel forms. With Indian artists combining craftsmanship

Motion Sensor Lights for Homes Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the love Home motion sensor lights are intelligent, smart solutions combining convenience, security, and energy efficiency. They use advanced motion sensors that automatically detect movement and only illuminate spaces when they are needed. This saves electricity and provides a hands-free lighting experience, perfect for hallways, entrances, or other outdoor areas. With cutting-edge sensor solutions,

₹253.3142

₹253.3142

EMI Communication Shielding Tape Becu Spring EMI Shielding Products EMC EMI Shielding Tape

For SaleEMI Communication Shielding Tape Becu Spring EMI Shielding Products EMC EMI Shielding Tape Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

PVC foam boards | PVC boards | PVC foam board price Category : Other - Home Surveillance Systems

(No Ratings Yet)

(No Ratings Yet)Spread the loveDEMAC Group, is the most trusted PVC & WPC board manufacturer in Kerala. Demac come in various colors, textures, and thicknesses to suit different design and functional requirements.Our products have many advantages such as waterproof, termite proof, fire resistant etc.WPC boards are known for being environmentally friendly as they utilize recycled materials and

Clip-on series EMI shielding gaskets for grounding and conduction Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Web Development Company in Himachal Category : Computers, Tablets & Network Hardware

(No Ratings Yet)

(No Ratings Yet)Spread the loveBoost your online presence with the best Web Development Company in Himachal. Simran IT Services offers professional, innovative solutions. Call +919418722224 or visit https://simranitservices.com/web-development-company-himachal/

₹211.2379

₹211.2379

Custom EMI Shielding Gaskets and Spring Beryllium Copper Gaskets for MRI Doors and Windows

For SaleCustom EMI Shielding Gaskets and Spring Beryllium Copper Gaskets for MRI Doors and Windows Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Smooth conductive springs provide efficient EMI protection Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Sawtooth electromagnetic shielding shrapnel Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveCompany Profile SHENZHEN EMIS ELECTRON MATERIALS CO., LTD was founded on Nov. 8th, 2006, which is a high-tech company mainly produces electromagnetic shielding materials with over 15 years of professional production plant and technology accumulation as well as perfect production technology and first-class quality assurance. The company’s fixed assets (RMB) amount Up to

Top 10 Motion Sensor Lighting Providers Category : Electronics

(No Ratings Yet)

(No Ratings Yet)Spread the loveDiscover the top 10 providers of motion sensor lighting – companies offering up-to-date smart lighting solutions for your spaces. Each one of these firms specializes in advanced sensor solutions ensuring minimum energy consumption, convenience, and security for residential, commercial, or industrial applications. By incorporating the latest motion sensor technology, these providers make automation

Repair Laptops Contact US Category : Computer Parts & Components

(No Ratings Yet)

(No Ratings Yet)Spread the loveWe are based in Dadar, some 100 miles north of Mumbai, where the costs are considerably lower than the major conurbations such as Bangalore, Mumbai and Delhi. We are happy to pass these cost advantages on to our clients. This means that we provide technical support services from as little as £4 ($6)

Best Pre-Wedding Photographer in Ahmedabad Category : Other - Camera & Photo

(No Ratings Yet)

(No Ratings Yet)Spread the loveShubh Vibez 1115, 11th Floor, A Block, Titanium Heights, Corporate Rd, Prahlad Nagar, Ahmedabad, Gujarat 380015 Welcome to Shubhvibez! We believe that every wedding is a work of art, and we’re excited to help you create a masterpiece of memories. Shubhvibez offers pre-wedding & wedding photography, where your love story is captured with

We repair and replace broken PSP (PlayStation Portable) screen Category : Game Consoles